Custom Automation Built Right, Supported for Life

We design, build, and support turnkey automation systems for Northeast Ohio manufacturers. From ground-up builds to legacy retrofits, we're the high-capability partner you wish you hired the first time.

Trusted by Leading Manufacturers

We've delivered automation solutions for these Northeast Ohio companies

Experts in precision metal fabrication, producing high-quality wire forms, metal stampings, and springs for diverse industrial applications.

Specialists in custom plastic thermoforming, offering rapid prototyping and production for vacuum-formed and pressure-formed plastic components.

A global leader in electrical connection and protection solutions, designing systems that safeguard mission-critical equipment, buildings, and processes.

A leading contract manufacturer of microprecision medical devices and implants, specializing in laser machining and vascular stent production.

The largest global manufacturer and distributor of clinical rehabilitation and sports medicine products, including brands like Biofreeze and TheraBand.

A solution-driven custom manufacturer for automotive and industrial markets, specializing in die cutting, acoustic insulation, and adhesive applications.

A full-service provider of custom merchandising displays and point-of-purchase (POP) solutions for global retail brands.

A global designer and manufacturer of automotive technology solutions for clean air, powertrain, and ride performance systems.

"Visionary upgraded our obsolete control system from the 80's with a modern PLC, display and programming. Everything works as it should. We are very happy with their services."

The High-Capability Partner You Wish You Hired the First Time

We fill the gap between enterprise "Goliaths" and job shops. Enterprise-level technical capability with local, responsive, partner-for-life support.

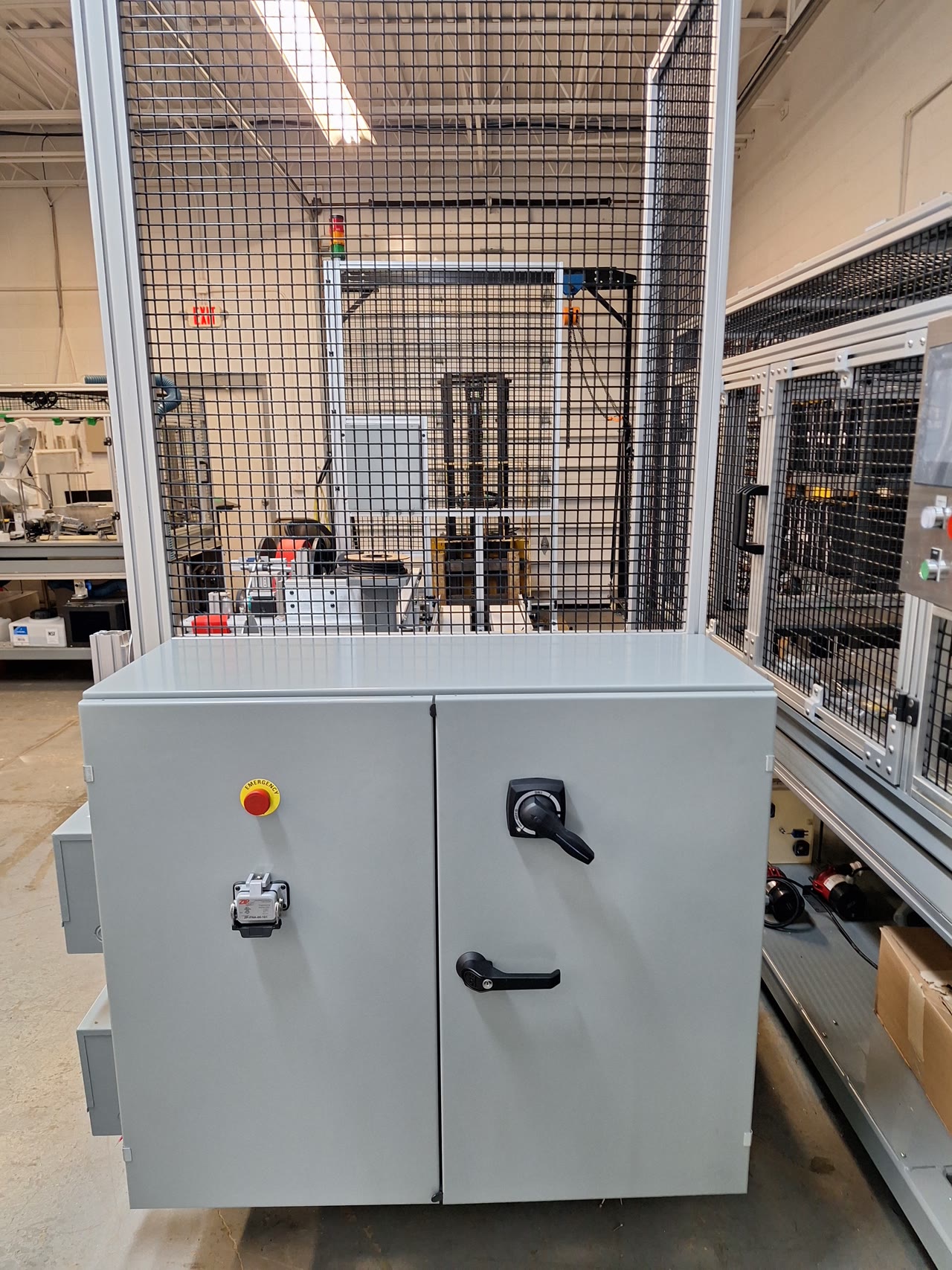

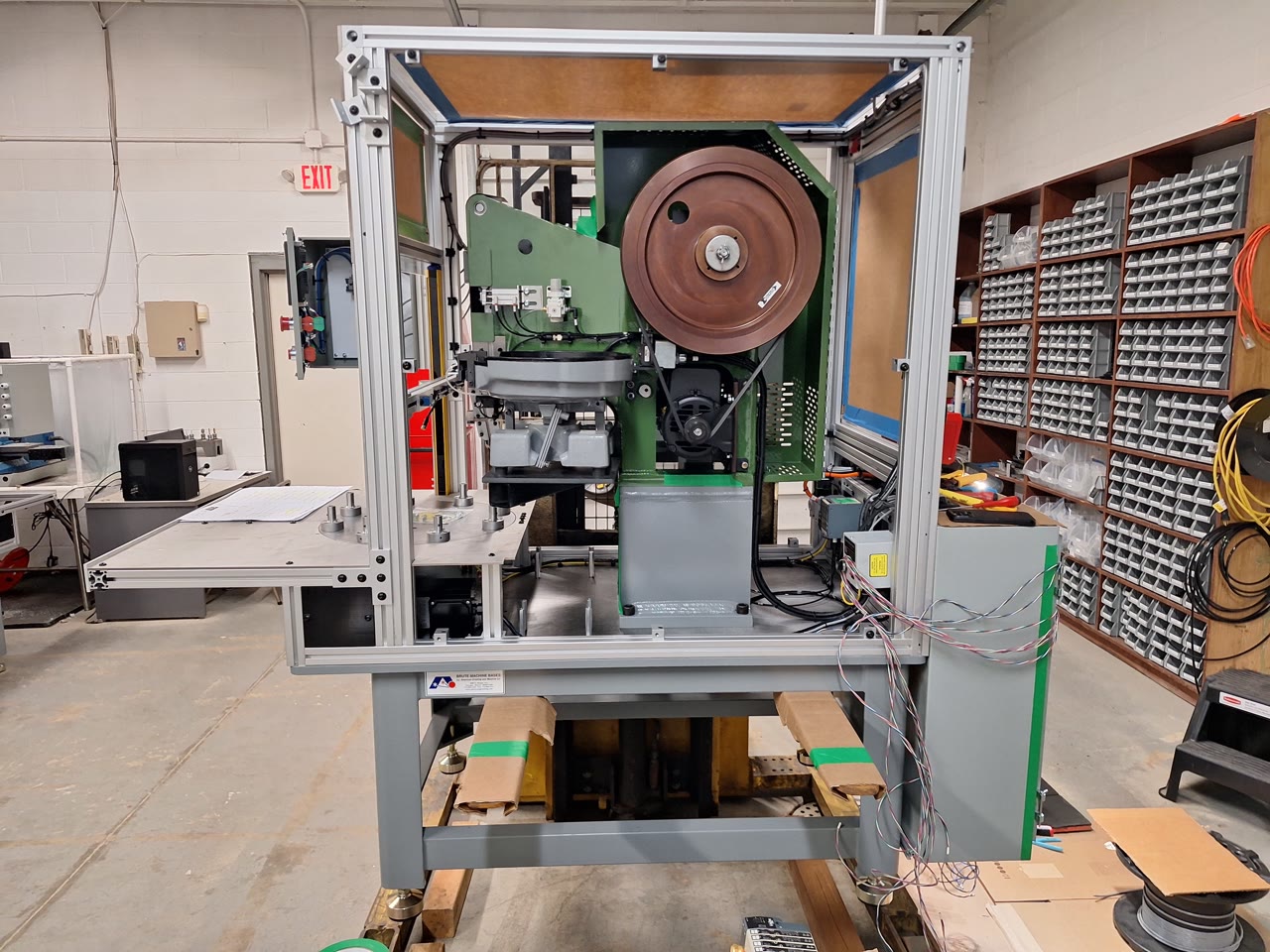

Turnkey Custom Builds

Ground-up automation systems from concept to commissioning. From simple fixtures to robotic cells projects completed on time.

Legacy Support & Retrofits

We fix machines others abandoned. Local, responsive support for repairs, upgrades, and modernization.

Advanced Integration

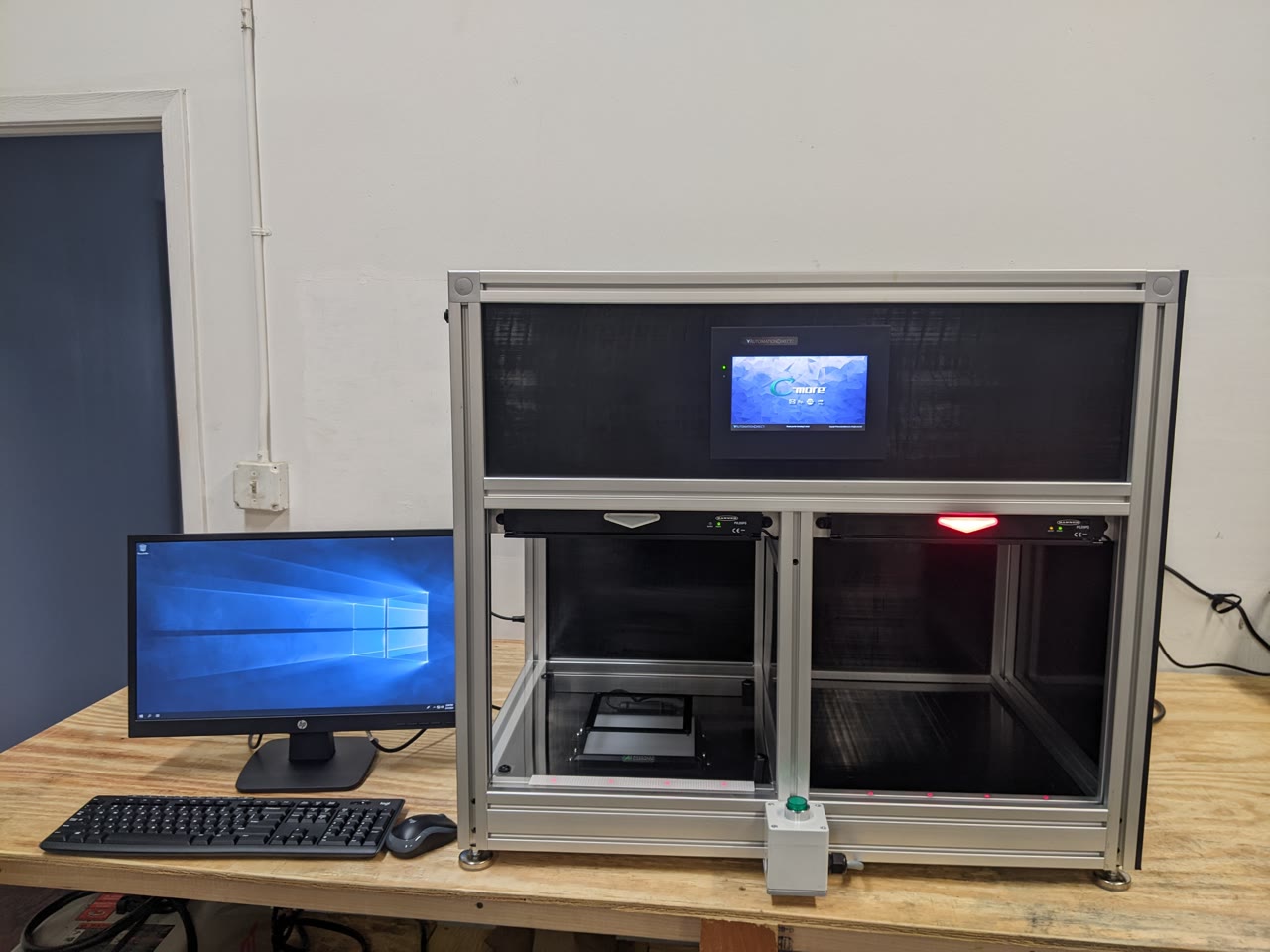

Robotic integration, machine vision, PLC programming, and SCADA systems for complex automation.

Proven Results for Northeast Ohio Manufacturers

From complete turnkey systems to targeted vision solutions, we deliver measurable ROI and long-term partnerships.

Our Capabilities

End-to-end automation solutions from design to ongoing support

Custom Turnkey Automation

Learn more about our expertise

PLC Programming & Controls

Learn more about our expertise

Robotic Integration

Learn more about our expertise

Machine Vision Systems

Learn more about our expertise

Legacy Support & Retrofits

Learn more about our expertise

Contract Manufacturing

Learn more about our expertise

Ready to Discuss Your Automation Project?

We're located in Twinsburg, Ohio and serve manufacturers throughout Northeast Ohio. Get a response within 24 hours.